How an aluminum smelter is made

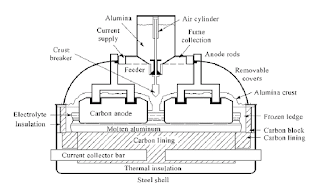

In an aluminum smelter usually we find several hundred pot, housed in

one or more large buildings called potrooms. Inside the potroom the

cells are electrically connected in series. This means that the cathode

of a cell is connected with the anode rod of the next cell downstream. The

electrical connection of one cell to the next one is made with a

complicated system of aluminum bars with cross sectional areas suitable

to transport the so high currents used with minimum voltage drops. In

the most recent smelters the cells are arranged in a side by side

configuration, which makes easier to lessen the adverse effects of the

magnetic fields. In older smelters it’s easy to find also the end-to-end

configuration.

As we have seen, a cell for its basic functioning needs alumina, carbon anodes and electrical current. In an aluminum smelter, hence, together with the potroom, we find other buildings and sub plants which deliver to the potroom carbon anodes, alumina and electrical current.

The carbon plant produces the anodes for the potroom. Anodes are made starting from petroleum coke, pitch and recycled butts. The coke is grinded in various fractions and then is mixed together with crushed butts and pitch. This mix is then heated and vigorously stirred in a plant called green mill. The green paste produced is then transferred into a vibrocompactor or a press in order to produce a so called green anode. Green anodes are then sent to the baking furnaces, where they are heated up and stay for some time at around 1100°C, until they form a solid block of carbon. The baked anode is then sent to the rodding room where it is coupled to the anode rod with cast iron. The rodded anodes are sent to the potroom generally through a conveyor. The rodding room also receives the spent anodes from the potroom. These spent anodes are cooled down, the remaining cover material is removed from the anode and the remaining part of the carbon is stripped from the rod. The carbon is then transported into the green mill where it will be reused to produce other new anodes. In the carbon plant are present also treatment systems for the gases produced by the baking of the anodes.

Alumina is transferred from the main smelter silos to the potroom usually by conveyors or air slides. Before entering into the potroom, the alumina is used to “clean” the gases evolving from the crust of the pot. The cleaning is realized finely mixing the fresh alumina with the hot gases escaping from the cells rich in fluoride. The alumina adsorbs on its surface the fluoride, which then goes back to the potroom together with the alumina.

The alternate current received from the external grid needs to be converted into a low voltage, high amperage direct current. This is done by a dedicated plant, which lowers the voltage with transformers and then rectifies the current using a series of diodes in parallel.

After the potroom it is placed the casthouse, which receives the molten metal produced by the cells and after some processes (skimmimg, degassing, alloying) produce the end products as ingots, billets or slabs

Established in 1995, and reformed to a shareholding enterprise in 2005, Zhengzhou Joda Technology Co., Ltd. is a modernized comprehensive enterprise integrating research, manufacture, export and technical service of various types of equipments for aluminum smelters all over the world. The scope of supply covers the complete range of R&D, consulting, feasibility studies, design, engineering, manufacturing, shipping, installation, commissioning, training and after sales services. Joda manufacturer automatic anode jacking frame, ladles accessories, aerogel insulation blanket, anode jacking system, Anode Clamp, bimetal, aluminum ladle cleaning machine, MTV tapping tube cleaner etc.

Cultivated with a craftsmanship for more than 20 years in aluminum field, and now we have become a modernized company with over 60000 m2 workshops and more than 500 employees and have supplied innovative, safe and reliable products, based on ISO 9001, ISO 14001 and OHSAS 18001 systems, for over 100 aluminum smelters in the world.

Company: Zhengzhou Joda Technology Co., Ltd.

Name: anna

Email: mxh@zzjoda.com

Web: www.anodejackingframe.com

Tel: +86 (0) 371 5517 8216

Fax: +86 (0) 371 5517 8216

Code:450016

As we have seen, a cell for its basic functioning needs alumina, carbon anodes and electrical current. In an aluminum smelter, hence, together with the potroom, we find other buildings and sub plants which deliver to the potroom carbon anodes, alumina and electrical current.

The carbon plant produces the anodes for the potroom. Anodes are made starting from petroleum coke, pitch and recycled butts. The coke is grinded in various fractions and then is mixed together with crushed butts and pitch. This mix is then heated and vigorously stirred in a plant called green mill. The green paste produced is then transferred into a vibrocompactor or a press in order to produce a so called green anode. Green anodes are then sent to the baking furnaces, where they are heated up and stay for some time at around 1100°C, until they form a solid block of carbon. The baked anode is then sent to the rodding room where it is coupled to the anode rod with cast iron. The rodded anodes are sent to the potroom generally through a conveyor. The rodding room also receives the spent anodes from the potroom. These spent anodes are cooled down, the remaining cover material is removed from the anode and the remaining part of the carbon is stripped from the rod. The carbon is then transported into the green mill where it will be reused to produce other new anodes. In the carbon plant are present also treatment systems for the gases produced by the baking of the anodes.

Alumina is transferred from the main smelter silos to the potroom usually by conveyors or air slides. Before entering into the potroom, the alumina is used to “clean” the gases evolving from the crust of the pot. The cleaning is realized finely mixing the fresh alumina with the hot gases escaping from the cells rich in fluoride. The alumina adsorbs on its surface the fluoride, which then goes back to the potroom together with the alumina.

The alternate current received from the external grid needs to be converted into a low voltage, high amperage direct current. This is done by a dedicated plant, which lowers the voltage with transformers and then rectifies the current using a series of diodes in parallel.

After the potroom it is placed the casthouse, which receives the molten metal produced by the cells and after some processes (skimmimg, degassing, alloying) produce the end products as ingots, billets or slabs

Established in 1995, and reformed to a shareholding enterprise in 2005, Zhengzhou Joda Technology Co., Ltd. is a modernized comprehensive enterprise integrating research, manufacture, export and technical service of various types of equipments for aluminum smelters all over the world. The scope of supply covers the complete range of R&D, consulting, feasibility studies, design, engineering, manufacturing, shipping, installation, commissioning, training and after sales services. Joda manufacturer automatic anode jacking frame, ladles accessories, aerogel insulation blanket, anode jacking system, Anode Clamp, bimetal, aluminum ladle cleaning machine, MTV tapping tube cleaner etc.

Cultivated with a craftsmanship for more than 20 years in aluminum field, and now we have become a modernized company with over 60000 m2 workshops and more than 500 employees and have supplied innovative, safe and reliable products, based on ISO 9001, ISO 14001 and OHSAS 18001 systems, for over 100 aluminum smelters in the world.

Company: Zhengzhou Joda Technology Co., Ltd.

Name: anna

Email: mxh@zzjoda.com

Web: www.anodejackingframe.com

Tel: +86 (0) 371 5517 8216

Fax: +86 (0) 371 5517 8216

Code:450016

Lipo Technology Private Limited is a trusted name among leading SS Cable Tie Manufacturers, offering durable and high-strength stainless steel cable ties designed for industrial, commercial, and heavy-duty applications. Our SS cable ties are corrosion-resistant, heat-resistant, and ideal for securing cables, pipes, and equipment in challenging environments. With a focus on quality and innovation, we deliver reliable fastening solutions that ensure safety and longevity. For enquiries, contact us at +91 9722266550.

回复删除