The Beam Of anode busbar jacking frame

The beam of the anode busbar jacking frame is the load-bearing beam in the process of anode busbar raising, the deflection deformation of the beam is required to be small when supporting the anode weight, to decrease the position of anode.

The beam structure uses the two sides adopting solid webs, weld as one through the steel trough, angle steel and other solid abdominal plates. The beam of this scheme is designed into a box-shaped structure, and the upper and lower surfaces are welded with steel plates, and set up the connector plate inside, the features of overall steel are good, low production cost, etc. With 4 support points, each support point set has two landing legs, the middle four are fixed length landing legs, the four both ends landing legs can retract lengths.

The upper part of the beam is arranged with two lifting racks, which facilitates the electrolytic multifunctional crane to swing frame.

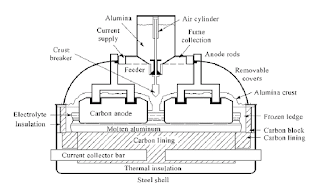

We have more than 670 sets of aluminum smelting equipment including welding, cutting and machining, and a metallic structural factory with main products of auto anode jacking frames, anode jacking systems, ladles, point feeders, crust breakers, anode clamps, anode assembly (steel yoke, anode rod, clad welded together), a foundry factory for all kinds of casting items, and an explosion factory for bi-metal transition blocks.

Our company has its own professional R & D team, dedicated to the development and production of SiO2 aerogels composite materials, the use of advanced supercritical CO2 fluid drying equipment to do aerogel drying, to ensure the quality of the product. I have a production line has been put into operation, can achieve 3000 cubic meters / year capacity. Is currently planning two, three of the construction, and ultimately can achieve an annual output of 20,000 cubic meters of production capacity.

source: http://www.anodejackingframe.com/productnew/beam-busbar-jacking-frame.html

评论

发表评论