There are two primary technologies using the Hall–Héroult process

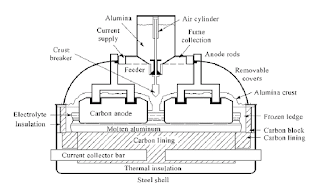

There are two primary technologies using the Hall–Héroult process: Söderberg technology and prebake technology. In Söderberg or self-baking anodes using cells, there is a single anode per electrolysis cell Aluminum smelter equipment . The anode is in a frame and as the bottom of the anode turns mainly into CO2 during the electrolysis the anode loses mass and being amorphous it slowly sinks within its frame. More material to the top of the anode is continuously added in the form of briquettes made from coke and pitch. The lost heat from the smelting operation is used to bake the briquettes into the carbon form required for reaction with alumina. This baking process in Söderberg anodes during electrolysis releases more carcinogenic PAHs and other pollutants than electrolysis with prebaked anodes and partially for this reason prebaked anodes using cells have become more common in aluminum industry. More alumina is added to the electrolyte from the sides of the Söderberg anode after the