Automatic Anode Jacking Frame is used to lift the anode busbar periodically

The automatic anode jacking frame, known as the busbar lifting frame, is used to lift the anode busbar periodically.

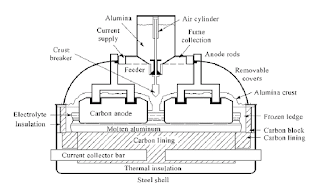

Automatic Anode Jacking Frame integrates the function of let-go and fastening Anode Clamp with the frame. Operations such as clamping of anode rods, holding the anode busbar and releasing the anode grabs can all be fulfilled by remote Control, so that the operation of raising anode busbar, which is needed periodically in a pot room, is greatly improved both in quality and in shorter time, esp. with lower electricity and labor consumption.

Our Automatic Anode Jacking Frame was highly evaluated during the Scientific Achievement Evaluation Conference held by China Nonferrous Association in June 2015. The automatic anode jacking frame has good technology reproducibility and high maturity. When using automatic anode jacking frame, the operators can be reduced from 11 to 4, and operating time can be shortened from 15-20 minutes to 4- 6 minutes, which can greatly improve working efficiency and also save significant labor cost, said the experts group.

Ever since the First Automatic Anode Jacking Frame was put into use in 2014, Zhengzhou Joda Technology Co., Ltd. has supplied over 20 new AJF and also upgraded over 50 old AJF for more than 30 electrolytic aluminum equipment both home and abroad. We have established long term cooperation with world-famous Crane manufacturer.

We carefully improve each AJF with listening to every client's feedback, to make sure our lead technical positions.

Mature & Stable

Full Remote Control

Significant Cost Saving

1:2 Air Amplifier

source: http://www.anodejackingframe.com

评论

发表评论