Manual anode busbar frame disadvantages

1. Fastening torque is uneven and inadequate, voltage drop is 13-15mv, which means high electricity consumption.

2. Uneven fastening torque will cause uneven current distribution and affect current effect of the pot shell.

3. The air pressure is required to be at least 0.62MPa and gas consumption is quite high (2.69 m3/min) sometimes other works has to be stopped when lifting the anode beam.

Automatic Anode Beam Raising Frames Advantages

1. 1:2 Air Amplifier

2. Full Remote Control

3. Patented Design

4. Significant Energy Saving

5. Turn-Key Solutions

Cultivated with a craftsmanship for more than 20 years in aluminum field, and now we have become a modernized company with over 60000 m2 workshops and more than 500 employees and have supplied innovative, safe and reliable products, based on ISO 9001, ISO 14001 and OHSAS 18001 systems, for over 100 electrolytic aluminum equipment in the world.

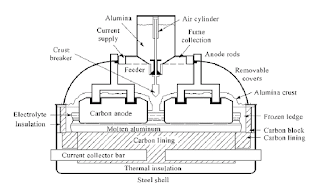

We have more than 670 sets of equipment including welding, cutting and machining, and a metallic structural factory with main products of auto anode jacking frames, anode jacking systems, ladles, point feeders, crust breakers, anode clamps, anode assembly (steel yoke, anode rod, clad welded together), a foundry factory for all kinds of casting items, and an explosion factory for bi-metal transition blocks.

评论

发表评论