There are two primary technologies using the Hall–Héroult process

There are two primary technologies using the Hall–Héroult process: Söderberg technology and prebake technology.

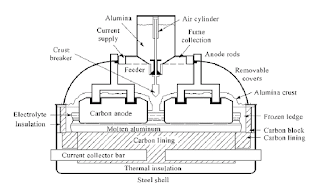

In Söderberg or self-baking anodes using cells, there is a single anode per electrolysis cell Aluminum smelter equipment. The anode is in a frame and as the bottom of the anode turns mainly into CO2 during the electrolysis the anode loses mass and being amorphous it slowly sinks within its frame. More material to the top of the anode is continuously added in the form of briquettes made from coke and pitch. The lost heat from the smelting operation is used to bake the briquettes into the carbon form required for reaction with alumina. This baking process in Söderberg anodes during electrolysis releases more carcinogenic PAHs and other pollutants than electrolysis with prebaked anodes and partially for this reason prebaked anodes using cells have become more common in aluminum industry. More alumina is added to the electrolyte from the sides of the Söderberg anode after the crust on top of the electrolyte mixture is broken.

Prebake technology is named after its anodes, which are baked in very large gas-fired ovens at high temperature before being lowered by various heavy industrial lifting systems into the electrolytic solution. There usually are 24 prebaked anodes in two rows in one cell. Each anode is lowered vertically and individually by a computer as the bottom surfaces of the anodes are eaten away during the electrolysis. Compared to Söderberg anodes computer controlled prebaked anodes can be brought closer to the molten aluminium layer at the bottom of the cell without any of them touching the layer and interfering with the electrolysis. This smaller distance decreases the resistance caused by the electrolyte mixture and increases the efficiency of prebaked anodes over Söderberg anodes. Prebake technology also has much lower risk of the anode effect happening, but cells using it are more expensive to build and labor-intensive to use as each prebaked anode in a cell needs to be removed and replaced once it has been used. Alumina is added to the electrolyte from between the anodes in prebake technology using cells.

Prebaked anodes contain a smaller percentage of pitch, as they need to be more solid than Söderberg anodes. The remains of prebaked anodes are used to make more new prebaked anodes. Prebaked anodes either are made in the same factory where electrolysis happens or are brought there from elsewhere.

In Söderberg or self-baking anodes using cells, there is a single anode per electrolysis cell Aluminum smelter equipment. The anode is in a frame and as the bottom of the anode turns mainly into CO2 during the electrolysis the anode loses mass and being amorphous it slowly sinks within its frame. More material to the top of the anode is continuously added in the form of briquettes made from coke and pitch. The lost heat from the smelting operation is used to bake the briquettes into the carbon form required for reaction with alumina. This baking process in Söderberg anodes during electrolysis releases more carcinogenic PAHs and other pollutants than electrolysis with prebaked anodes and partially for this reason prebaked anodes using cells have become more common in aluminum industry. More alumina is added to the electrolyte from the sides of the Söderberg anode after the crust on top of the electrolyte mixture is broken.

Prebake technology is named after its anodes, which are baked in very large gas-fired ovens at high temperature before being lowered by various heavy industrial lifting systems into the electrolytic solution. There usually are 24 prebaked anodes in two rows in one cell. Each anode is lowered vertically and individually by a computer as the bottom surfaces of the anodes are eaten away during the electrolysis. Compared to Söderberg anodes computer controlled prebaked anodes can be brought closer to the molten aluminium layer at the bottom of the cell without any of them touching the layer and interfering with the electrolysis. This smaller distance decreases the resistance caused by the electrolyte mixture and increases the efficiency of prebaked anodes over Söderberg anodes. Prebake technology also has much lower risk of the anode effect happening, but cells using it are more expensive to build and labor-intensive to use as each prebaked anode in a cell needs to be removed and replaced once it has been used. Alumina is added to the electrolyte from between the anodes in prebake technology using cells.

Prebaked anodes contain a smaller percentage of pitch, as they need to be more solid than Söderberg anodes. The remains of prebaked anodes are used to make more new prebaked anodes. Prebaked anodes either are made in the same factory where electrolysis happens or are brought there from elsewhere.

Fax: +86 (0) 371 5517 8216

QQ: 413669179

评论

发表评论